Rangefinder camera + Folder camera = RangeFolder, a new word that I created, and a new camera out of old ones.

Tuesday, June 30, 2009

I am learning to us twitter, as "salihonba" on line, eyes wide shot. Follow me, let me follow you.

Monday, June 29, 2009

Full metal jacket

Take it easy, almost there, but not yet.

It is a jacket, for 110b, actually, for all series cameras that Polaroid use the similar body.

It is a prototype, many test screw holes, but the screw hole for tripod is set tight in the middle of the body, not like the original, set aside to avoid structures inside, always worry about the balance.

When Grafmatic holder is put on, pliers hold it deadly tight, I am happy with that.

Thought it's a fat boy in thickness, but at my tolerance, still keep the outlook slim and stylish.

And for double-sided film holder, still good at holding, though I do not think that this kind of film holders will be a good idea for snapshooting. Just imaging that, while you shooting, draw out the film mask, and then? You are now a mask in hand, how are you going to deal with it?

Jacket put on, pity I cut the wrong size of left handle cover, will change it in the end.

It is a jacket, for 110b, actually, for all series cameras that Polaroid use the similar body.

| From Drop Box |

It is a prototype, many test screw holes, but the screw hole for tripod is set tight in the middle of the body, not like the original, set aside to avoid structures inside, always worry about the balance.

| From Drop Box |

When Grafmatic holder is put on, pliers hold it deadly tight, I am happy with that.

| From Drop Box |

Thought it's a fat boy in thickness, but at my tolerance, still keep the outlook slim and stylish.

| From Drop Box |

And for double-sided film holder, still good at holding, though I do not think that this kind of film holders will be a good idea for snapshooting. Just imaging that, while you shooting, draw out the film mask, and then? You are now a mask in hand, how are you going to deal with it?

| From Drop Box |

Jacket put on, pity I cut the wrong size of left handle cover, will change it in the end.

| From Drop Box |

| From Drop Box |

Friday, June 26, 2009

Is it the bellows you want?

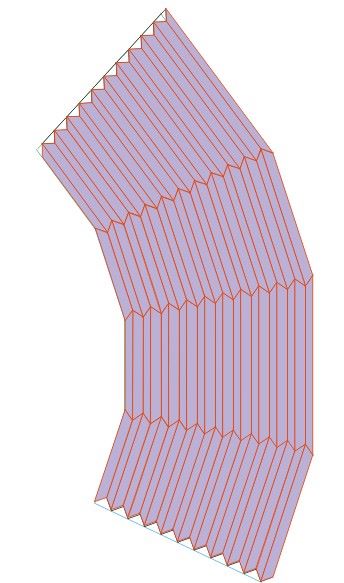

Now we are at the key point of bellows making.

You have draw the frame, according the dimension you need, and hopefully make a bellows exactly fit your camera.

But I tell you, you are not.

Your bellows will be too small for your frame, front and back.

Let me show you why.

It is 120mm we need for back opening, if you remember. And that was not defined by first rib, the first rib will be folded in and glued to the second rib, so it is the second rib really counts.

The real dimension I show you in the picture tells you, your bellows is too small, only 117.6mm on this side, not 120mm. That yellow rib, will be folded in and glued with the second one.

Other instruction will suggest to make some bellows in paper, measure the sizes of opening, then modify, and make another one paper model, measure, modify again...... till you satisfied.

Well, I like to make things correct in one shot.

Draw line on the tip of triangles, extend it out of the shape, then move the triangles align the line, till first tip reaches the edge of the shape.

Now let me show you the dimension of the second rib became 119.7mm, very much closed to the size we need.

But if you think we are there now, then you are wrong again!

Since bellows is not made by air, it got thickness, some people quit making bellows themselves just because they can't find material thin enough, bellows is too thick squeezing into camera body.

My material produces 0.25-0.3mm thickness when 3 layers combined, and two sides makes 0.5-0.6mm space occupied, so if you are happy with 119.7mm, thinking that is good enough for 120mm, then at final your bellows only got 119.2mm in the best situation, most of time you get merely 118.5 max.

That is fine to you? well, not me.

I can not tolerate letting negative space wasted even 0.1mm in length, it is so precious.

So here we go on next step, give them more spaces.

Stretch green shape 1mm downward,

and move triangles align the down edge.

Now the edge size for 2nd ribs becomes 120.7mm, enough for opening and layer thickness. In many cases, I will leave 2mm more for it, a bigger opening is better than a smaller one.

Now you are making a bellows that really fit your need!

Inspired by green shape, blue shape also stretch 1mm, upward. Then rotate blue shape, align the base line of triangles, meet the first triangle's tip. For showing their relations more clearly, I take off the color of two shapes, instead of colored frames. Here you will notice that two shapes intersect with each other on border.

Then copy green shape with triangles to other side of blue shape.

Copy again, this time the blue shape with triangles to other side of green shape.

There we are, guides for four sides are finished. Based on these guides, we are now connect each tip into a rib.

finish all the ribs, and now we are almost done.

You can check each side's dimension, to see if they fit your need.

Then now comes the final step, spaces between the ribs. For bellows at 4x5 format or smaller, 1.2~1.5mm space is acceptable, use the spacing option or outline option in graphic program, you can easily adjust spaces between these ribs, then they are done, ready for plotter.

Now I need rest.

You have draw the frame, according the dimension you need, and hopefully make a bellows exactly fit your camera.

But I tell you, you are not.

Your bellows will be too small for your frame, front and back.

Let me show you why.

It is 120mm we need for back opening, if you remember. And that was not defined by first rib, the first rib will be folded in and glued to the second rib, so it is the second rib really counts.

The real dimension I show you in the picture tells you, your bellows is too small, only 117.6mm on this side, not 120mm. That yellow rib, will be folded in and glued with the second one.

|

| From Drop Box |

Other instruction will suggest to make some bellows in paper, measure the sizes of opening, then modify, and make another one paper model, measure, modify again...... till you satisfied.

Well, I like to make things correct in one shot.

Draw line on the tip of triangles, extend it out of the shape, then move the triangles align the line, till first tip reaches the edge of the shape.

|

| From Drop Box |

Now let me show you the dimension of the second rib became 119.7mm, very much closed to the size we need.

|

| From Drop Box |

But if you think we are there now, then you are wrong again!

Since bellows is not made by air, it got thickness, some people quit making bellows themselves just because they can't find material thin enough, bellows is too thick squeezing into camera body.

My material produces 0.25-0.3mm thickness when 3 layers combined, and two sides makes 0.5-0.6mm space occupied, so if you are happy with 119.7mm, thinking that is good enough for 120mm, then at final your bellows only got 119.2mm in the best situation, most of time you get merely 118.5 max.

That is fine to you? well, not me.

I can not tolerate letting negative space wasted even 0.1mm in length, it is so precious.

So here we go on next step, give them more spaces.

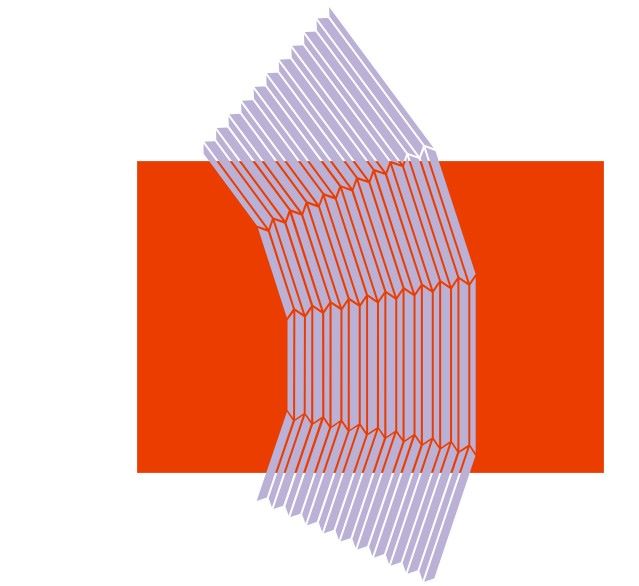

Stretch green shape 1mm downward,

|

| From Drop Box |

|

| From Drop Box |

Now the edge size for 2nd ribs becomes 120.7mm, enough for opening and layer thickness. In many cases, I will leave 2mm more for it, a bigger opening is better than a smaller one.

|

| From Drop Box |

Now you are making a bellows that really fit your need!

Inspired by green shape, blue shape also stretch 1mm, upward. Then rotate blue shape, align the base line of triangles, meet the first triangle's tip. For showing their relations more clearly, I take off the color of two shapes, instead of colored frames. Here you will notice that two shapes intersect with each other on border.

|

| From Drop Box |

Then copy green shape with triangles to other side of blue shape.

|

| From Drop Box |

Copy again, this time the blue shape with triangles to other side of green shape.

|

| From Drop Box |

There we are, guides for four sides are finished. Based on these guides, we are now connect each tip into a rib.

|

| From Drop Box |

finish all the ribs, and now we are almost done.

|

| From Drop Box |

You can check each side's dimension, to see if they fit your need.

|

| From Drop Box |

Then now comes the final step, spaces between the ribs. For bellows at 4x5 format or smaller, 1.2~1.5mm space is acceptable, use the spacing option or outline option in graphic program, you can easily adjust spaces between these ribs, then they are done, ready for plotter.

|

| From Drop Box |

|

| From Drop Box |

Now I need rest.

Bellows in shape

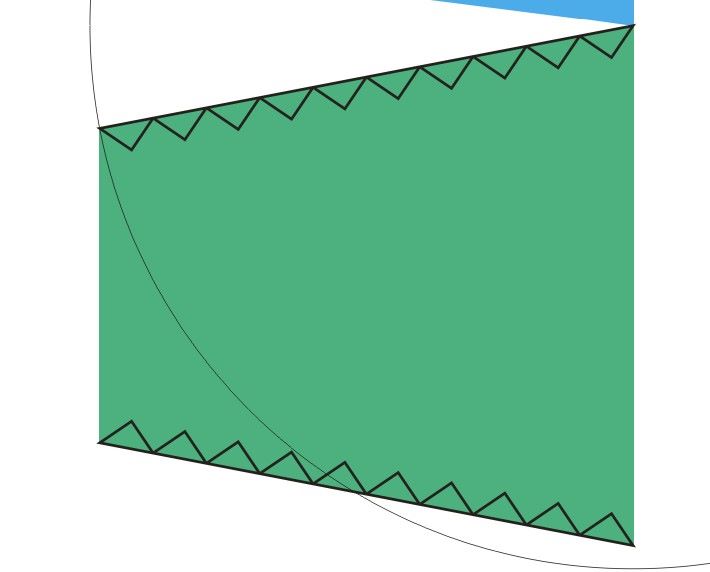

There are three most important measures you need to know before making bellows.

1. the opening size of front/back frame.

2. the rib width.

3. the length when bellows totally unfolded.

As for a bellows for 4x5 format, the back opening should be 90x120mm in standard size, but sometimes it changes a little bit, depend on the cameras, there always a frame pasted on it, to fix the shape and fix the back into back stand of the camera body.

I choose 95x120mm as back size in my Polaroid 110B conversion project.

And the front opening, depend on the front frame. The frame, with a round for lens to go through, and four tiny hole for screw, to fix to the front stand. For those old folders, there always no screws for the frame, just used glue.

In the pictures below, you can see one of my favorite folder- Kodak No.1 special, and a bellows tear from 110A. folder had been replaced old ragged bellows into my silk one, shows its quality under the sun.

Now as an example, let's assume the rib width is 7mm, and the length of bellows is 140mm when totally unfolded. Measure your front and back opening sizes, and draw them in graphic program, I use CorelDraw if you asked, thank you. In this example, the front/back frame will be 60x67mm, 95x120mm.

Then add the rib size for them, 7mm in rib width is common for most bellows under 4x5 format, remember to chamfer on each corner. Outer size now became 74x81mm, 109x134mm.

If you ask me why it is 7mm in width? Then it relates to trigonometric function I guess. You see, the width of bevel edge comes from the sum of the square of two other sides as in pictures below, nearly 10mm, very easy to draw for the days when all things need to be done in hands, that's why.

Now connect the outer edges of the two correspond sides of front and back opening, form a ladder-shaped, you need two of these, showed in green and blue color in picture.

then turn the horizon one into vertical, and right-aligned with the other. For next step, two shapes meet each other with their end points.

Using the meeting point as center of circle, draw a circle, radius is what your bellows' length, in here, radius is 140mm.

Then stretch two ladder-shape to left, make their side extended just as long as radius of the circle.

This ensures that two ladder-shapes will have the same length in bevel side. You can skip this if the bellows got the same size of front/back opening.

Now the time to draw ribs.

We set this bellows in 140mm in length, so we draw 10 circle side by side, from the tip where shapes meet to the end of big circle, in 14mm diameter.

And then change circle into rectangles.

all we need is half part of these rectangles, cut the upper half, then we rotate them, align the edges of the shape.

1. the opening size of front/back frame.

2. the rib width.

3. the length when bellows totally unfolded.

As for a bellows for 4x5 format, the back opening should be 90x120mm in standard size, but sometimes it changes a little bit, depend on the cameras, there always a frame pasted on it, to fix the shape and fix the back into back stand of the camera body.

I choose 95x120mm as back size in my Polaroid 110B conversion project.

And the front opening, depend on the front frame. The frame, with a round for lens to go through, and four tiny hole for screw, to fix to the front stand. For those old folders, there always no screws for the frame, just used glue.

In the pictures below, you can see one of my favorite folder- Kodak No.1 special, and a bellows tear from 110A. folder had been replaced old ragged bellows into my silk one, shows its quality under the sun.

| From Drop Box |

Now as an example, let's assume the rib width is 7mm, and the length of bellows is 140mm when totally unfolded. Measure your front and back opening sizes, and draw them in graphic program, I use CorelDraw if you asked, thank you. In this example, the front/back frame will be 60x67mm, 95x120mm.

|

| From Drop Box |

Then add the rib size for them, 7mm in rib width is common for most bellows under 4x5 format, remember to chamfer on each corner. Outer size now became 74x81mm, 109x134mm.

|

| From Drop Box |

If you ask me why it is 7mm in width? Then it relates to trigonometric function I guess. You see, the width of bevel edge comes from the sum of the square of two other sides as in pictures below, nearly 10mm, very easy to draw for the days when all things need to be done in hands, that's why.

|

| From Drop Box |

Now connect the outer edges of the two correspond sides of front and back opening, form a ladder-shaped, you need two of these, showed in green and blue color in picture.

|

| From Drop Box |

then turn the horizon one into vertical, and right-aligned with the other. For next step, two shapes meet each other with their end points.

|

| From Drop Box |

Using the meeting point as center of circle, draw a circle, radius is what your bellows' length, in here, radius is 140mm.

|

| From Drop Box |

Then stretch two ladder-shape to left, make their side extended just as long as radius of the circle.

|

| From Drop Box |

This ensures that two ladder-shapes will have the same length in bevel side. You can skip this if the bellows got the same size of front/back opening.

Now the time to draw ribs.

We set this bellows in 140mm in length, so we draw 10 circle side by side, from the tip where shapes meet to the end of big circle, in 14mm diameter.

|

| From Drop Box |

And then change circle into rectangles.

|

| From Drop Box |

all we need is half part of these rectangles, cut the upper half, then we rotate them, align the edges of the shape.

|

| From Drop Box |

|

| From Drop Box |

bellows in silk

I made bellows for folders many years, the material I use are light proof nylon cloth for covering, cutting sheets as ribs, and cotton cloth for inner. I am not happy with the quality and the touching feeling of the nylon, but before other light-proof material and thin enough and affordable can be found, I had to live with it. It is the only layer that mask almost light out of the bellows, of course ribs can do the rest job.

Recently I changed my point of view. Since bellows is made by 3 kind of layers, to mask all the light, then I can use any material that is thin enough to make, as they block the light out when 3 layers are merged.

Acrylic paint, that is the key.

Before the layer merged, brush few times the paint on it, block all pin holes in cloth, check it under the sun, till it became opaque all over.

That widen my choice of the material, now I choose silk, because I can find many silk sheets in beautiful patterns, and they will shine under the sun.

And the ribs, those little ribs keeps people trying to make bellows themselves, all the references I can find, instructed people to cut the ribs one by one by hand, carefully measured, and then pasted them one by one by hand, to the cloth, just imagine the job and time you need!!

Cutting sheet, that broadly used for shop sign, is what I use to as ribs, they can be cut by plotter, very accurate, and self adhesive on one side, so cutting was replaced by computer, and pasting ribs can be done in one minute, all in one time!

And because I replace the job from hand by computer, a graphics program is needed. the pattern is changed, ribs are all pointed angles at sides, compared to traditional way, there are two sides of ribs in rectangle shape.

Recently I changed my point of view. Since bellows is made by 3 kind of layers, to mask all the light, then I can use any material that is thin enough to make, as they block the light out when 3 layers are merged.

Acrylic paint, that is the key.

Before the layer merged, brush few times the paint on it, block all pin holes in cloth, check it under the sun, till it became opaque all over.

That widen my choice of the material, now I choose silk, because I can find many silk sheets in beautiful patterns, and they will shine under the sun.

| From Drop Box |

And the ribs, those little ribs keeps people trying to make bellows themselves, all the references I can find, instructed people to cut the ribs one by one by hand, carefully measured, and then pasted them one by one by hand, to the cloth, just imagine the job and time you need!!

Cutting sheet, that broadly used for shop sign, is what I use to as ribs, they can be cut by plotter, very accurate, and self adhesive on one side, so cutting was replaced by computer, and pasting ribs can be done in one minute, all in one time!

And because I replace the job from hand by computer, a graphics program is needed. the pattern is changed, ribs are all pointed angles at sides, compared to traditional way, there are two sides of ribs in rectangle shape.

|

| From Drop Box |

Wednesday, June 24, 2009

Tenax 6x9 camera-2

As I received the camera body, bellows seems OK, so I quickly mounted the Optar 65/6.8 on it. The lens was for 6x9, for mounting it on, I had to take down parts of the front stand, like the waist level viewfinder, and the cover that just for masking some spring and screws.

Just fit the camera, could be totally fold up when this lens mounted, that released me. I don't want to make a folder that can not fold up when not in use.

Infinity stop was set for 105mm, now I need to reset it into the proper place, unscrewing the stopper, and I used AB glue to do the job, it is done!

I took it to HK for a short time trip, make some negs in the park, and found out that the "looks ok" bellow is not ok, so I changed it with one I made with silk and cotton cloth.

The viewfinder I used was one for cosina 25mm lens, borrowed from my another camera, for not to drill holes on camera body, I used magnet.

Then I changed the viewfinder with a Helios, round shape looks fine with the camera.

I also spay flat black paint on bed, preventing any reflection, and found one 37mm lens hood for it.

The magnet, glued with AB glue, on the cold shoe, then viewfinder mount on, and then you can stick it on any place you want to.

Besides infinity focus, I set some distance scale with tiny color lines by the side of bed, it can focus as close as 30cm.

But actually I planed to do, is to stick this scale on the flat bed, when move the lens on rail, you know where you are focusing.

Talked about to re-scale the distance, what I use is a magnifier, a caliper, and some cardboard, tapes.

put them onto the back of the body, focus to the mountain at distance, then you can redefined the infinity, then 3m, 1m 0.6m.....so on.

Tenax camera is easy to converting into a wide angle folder.

But next time I will try to use a Cocarette body, even better design and construction.

Just fit the camera, could be totally fold up when this lens mounted, that released me. I don't want to make a folder that can not fold up when not in use.

| From WA 6x9 folder in my pocket project |

Infinity stop was set for 105mm, now I need to reset it into the proper place, unscrewing the stopper, and I used AB glue to do the job, it is done!

| From WA 6x9 folder in my pocket project |

I took it to HK for a short time trip, make some negs in the park, and found out that the "looks ok" bellow is not ok, so I changed it with one I made with silk and cotton cloth.

The viewfinder I used was one for cosina 25mm lens, borrowed from my another camera, for not to drill holes on camera body, I used magnet.

| From WA 6x9 folder in my pocket project |

Then I changed the viewfinder with a Helios, round shape looks fine with the camera.

| From WA 6x9 folder in my pocket project |

I also spay flat black paint on bed, preventing any reflection, and found one 37mm lens hood for it.

The magnet, glued with AB glue, on the cold shoe, then viewfinder mount on, and then you can stick it on any place you want to.

| From WA 6x9 folder in my pocket project |

| From WA 6x9 folder in my pocket project |

Besides infinity focus, I set some distance scale with tiny color lines by the side of bed, it can focus as close as 30cm.

| From WA 6x9 folder in my pocket project |

But actually I planed to do, is to stick this scale on the flat bed, when move the lens on rail, you know where you are focusing.

|

| From WA 6x9 folder in my pocket project |

Talked about to re-scale the distance, what I use is a magnifier, a caliper, and some cardboard, tapes.

| From WA 6x9 folder in my pocket project |

put them onto the back of the body, focus to the mountain at distance, then you can redefined the infinity, then 3m, 1m 0.6m.....so on.

| From WA 6x9 folder in my pocket project |

| From WA 6x9 folder in my pocket project |

Tenax camera is easy to converting into a wide angle folder.

But next time I will try to use a Cocarette body, even better design and construction.

Tuesday, June 23, 2009

Tenax 6x9 camera

At first I did a lot of research, trying to find a proper folder, who has a focus device on the body, not on lens itself. That filtered many 69 folders out, although they still have very sturdy body construction, but unfortunately, impossible to replace the lens, and still keep the focus device on it.

During research, I fell in love with Ansco Viking 45, a neat body design, and the bellows it has still looks like brand new one, so I bought it, cost not much.

But the problem showed when I received it, the helical focus ring did not work, just sticked with the lens! I found out then these camera series all got the same problems, maybe the lubricant it used become sticky when aged, and made lens element malfunction.

Aside the lens, all other parts are so good, and the design looks so pretty, I don't want to give it up, so I bought another lens, a Radionar 105/4.5, asked repairman to replace it for me. Now it became one of my ever ready rangefolder.

Well, back to the topic.

Tenax camera got more than 80 years old, and I picked it when I knew it got focus knob on flat bed, instead on the lens, and that means you can replace it with any lens, as front stand can take.

There was one camera body for bid on internet, missing the lens, that is alright to me, and the bellows got leaking, also no problem to me, so I took it.

During research, I fell in love with Ansco Viking 45, a neat body design, and the bellows it has still looks like brand new one, so I bought it, cost not much.

| From WA 6x9 folder in my pocket project |

| From WA 6x9 folder in my pocket project |

| From WA 6x9 folder in my pocket project |

But the problem showed when I received it, the helical focus ring did not work, just sticked with the lens! I found out then these camera series all got the same problems, maybe the lubricant it used become sticky when aged, and made lens element malfunction.

Aside the lens, all other parts are so good, and the design looks so pretty, I don't want to give it up, so I bought another lens, a Radionar 105/4.5, asked repairman to replace it for me. Now it became one of my ever ready rangefolder.

| From WA 6x9 folder in my pocket project |

Well, back to the topic.

Tenax camera got more than 80 years old, and I picked it when I knew it got focus knob on flat bed, instead on the lens, and that means you can replace it with any lens, as front stand can take.

There was one camera body for bid on internet, missing the lens, that is alright to me, and the bellows got leaking, also no problem to me, so I took it.

| From WA 6x9 folder in my pocket project |

Subscribe to:

Posts (Atom)