One of my craftsman got stroke this summer while he practiced Japanese sword art, and still in coma now. But another craftsman just past away today......

My deepest.......don't know what to say.

Sad.

12/16 This morning is a cold and rainy day, sky looks dull and dark, I will go to see my pal last time, depressed....

12/19 Went to my craftsman's house again, Taipei is still raining, his family wept, including me.

12/20 Found one craftsman, who is old friend of the deceased, talked and he is willing to help, today I will go to his studio, and discuss with him, try to re-connect the job.

12/21 The one I worked with, intended to replace the deceased craftsman, is dis-qualify, I was disappointed with his work hobbit, and carelessly attitude, will find another one to cooperate.....

Rangefinder camera + Folder camera = RangeFolder, a new word that I created, and a new camera out of old ones.

Friday, December 16, 2011

Wednesday, December 14, 2011

Courses keep growing

Anyone notice the courses are going to bellows making already?

http://salihonbashome.blogspot.com/p/byron-diy-workshop.html

http://salihonbashome.blogspot.com/p/byron-diy-workshop.html

Monday, November 7, 2011

Course instructions keep on growing.....

Please refer the related web page....

page contents will keep growing, until a chapter is finished, then goes to next chapter.

Class, if you are confused on specific step, write to me, let me know.

11/28 add

tomorrow will be back home, then Xenotar new front standard is going to released.

page contents will keep growing, until a chapter is finished, then goes to next chapter.

Class, if you are confused on specific step, write to me, let me know.

11/28 add

tomorrow will be back home, then Xenotar new front standard is going to released.

Wednesday, November 2, 2011

Workshop courses will post online gradually

If you look carefully, will notice that I add a webpage named "Byron DIY workshop". That is for participants to follow the steps during DIY building their own Byron. However, some of the steps I think which are proper for anyone who is interested to learn some tips on DIY, may be post as public article. Some will be reserved for participants only.

The contents will be huge, and complicated, I hope to write in more detail and best with lots of photos and videos, so the posts will be add gradually, even will be refined if in need.

I am not a full time Byron camera builder, so all the time I can use is when I am off the job, please forgive the situation, but first course will be finished by this weekend.

The contents will be huge, and complicated, I hope to write in more detail and best with lots of photos and videos, so the posts will be add gradually, even will be refined if in need.

I am not a full time Byron camera builder, so all the time I can use is when I am off the job, please forgive the situation, but first course will be finished by this weekend.

Sunday, October 23, 2011

Wednesday, October 19, 2011

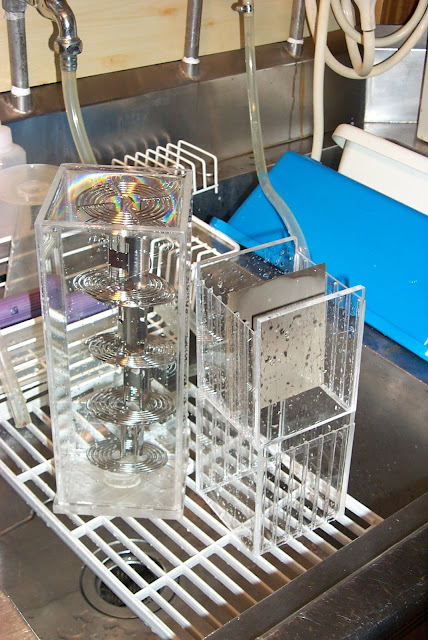

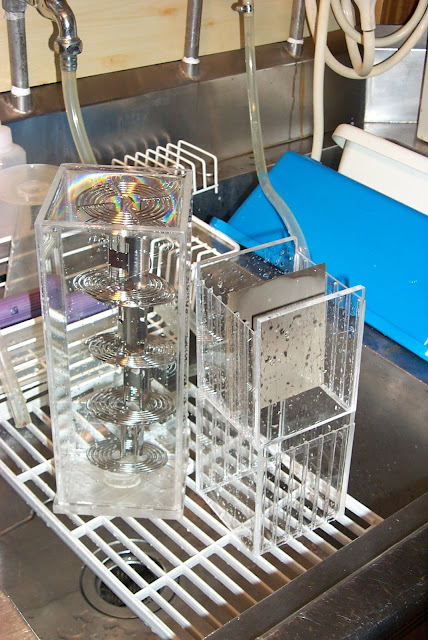

Modified sheet film washer

I modified a Kostiner roll film washer for both sheet/ roll film, it was ten years ago.

Kostiner film washer is a tube style in round shape, for it is designed for 135/ 120 roll film, sink developed film rolls into tube, let running water flow from bottom and overflow on top, with bubble generated with water, to clean films.

Round shape tube makes sheet film hard to use, and I managed to modify it into sheet/roll film washer.

1. Cut out the tube, leave square shape washer base, and re-glue the tube into a square shape.

Kostiner film washer is a tube style in round shape, for it is designed for 135/ 120 roll film, sink developed film rolls into tube, let running water flow from bottom and overflow on top, with bubble generated with water, to clean films.

Round shape tube makes sheet film hard to use, and I managed to modify it into sheet/roll film washer.

1. Cut out the tube, leave square shape washer base, and re-glue the tube into a square shape.

2. Build sheet film hanger box, each box can hold 6 sheet films, 2 boxes make 12 sheet films washed at the same time.

3. Test, found out that film hanger needs to keep films in position to prevent running water brings films away. Washer holds four 120 format film rolls at same time.

4. For even better foolproof when inserting film into ditches, make separation of each film with arcylic tubes, effects are great!

5. Finally, build some small boxes to hold one hanger only, so I can use them as film fixer container or for water stain remover. I use BTZS tubes to develop films, and with this box, 500 c.c. of fixer can easily do their job, and this way I don't have to worry scratches generated during fixing step.

|

Sunday, October 2, 2011

Byron workshop, half DIY your own camera!

Time's up, thanks for the mails who are interested in the course. To those who receive confirmed mail for workshop, please send US$900 to my Paypal account sali.honba@msa.hinet.net, and prepare your camera + lenses, we should start at the end of this month.

Daniel

Tim wrote to me and he makes the point, that I set the deadline of application at 10/16, how come I reject others before the date?

So I will leave 2 more participants available for who send mails to me before 10/16, candidates will be considered after the date arrived, so no hurry, take your time, just send your mail before 10/16.

thank you very much.

6 participants, hope I can handle that well.....

***

Amazingly, 6 appliers for workshop already, so please do not send your mail to me now, workshop takes four participants only. thank you very much. Daniel

***

I've been thinking about this recently, since one of my craftsman got stroke months ago, I can't stop wondering, what if I GOT stroke, will my unique Polaroid 4x5 conversion discontinued?

Pass my thought to friends, and thinking of letting more people could own Byron camera, I would held an experimental workshop, to help participant build one.

But the procedure could be very difficult if all by instructions only, there are some steps which needs special tooling, and some steps need CNC lathe machine, not everyone could find a helping hand around.

So I will ask participants follow my instruction, in some steps, to send their parts to me, I will help them to finish those steps, and then let them go on to next step.

I envision there will be about two steps for sending back parts, by sending back their parts, I will enclose all the parts needed for building Byron, including those tailored parts that I designed, exclusive for Byron.

The most complicated parts now I think most people will encounter, will be at the step building bellows, not yet decide whether I will make one for each other, or let them try, so there will be sort of experiments in it, participant not only need to be skillful on DIY, prepare all kinds of hand tools, and need a lot of patience, willing to help me to perfect the instruction, so there will be one complete instruction left when the camera is build, workshop at the end.

Workshop will take about 3 months for the course. It should start at the end of this month. Instruction will be released one by one, as a step for every two weeks,

Cost will be US$900, including all parts and two shipping postage during the course, but I am asking if anyone is interested in this way of DIY, let me know, mail me, all I need is about 4 participants, besides hand tools, you have to prepare your own Polaroid 110B plus lenses you choose, (or 110A + 900) and the conversion type (limited in Type A or B), drop me a mail, we could communicate privately.

If you are interested in this way, please let me know before 10/16. You are not really in the workshop by sending mail, just let me know if there are people who are interested.

thank you very much.

Daniel

salihonba@gmail.com

ps. DIY instructions will not be published in public, only participants are allowed to login and read it.

You can choose one Prime lens for matching cam curve, that is, your range-coupled lens. I will grind the cam curve for you, but I need you send the lens to me. other lenses you choose for Byron will be un-coupled range finding.

Daniel

Tim wrote to me and he makes the point, that I set the deadline of application at 10/16, how come I reject others before the date?

So I will leave 2 more participants available for who send mails to me before 10/16, candidates will be considered after the date arrived, so no hurry, take your time, just send your mail before 10/16.

thank you very much.

6 participants, hope I can handle that well.....

***

Amazingly, 6 appliers for workshop already, so please do not send your mail to me now, workshop takes four participants only. thank you very much. Daniel

***

I've been thinking about this recently, since one of my craftsman got stroke months ago, I can't stop wondering, what if I GOT stroke, will my unique Polaroid 4x5 conversion discontinued?

Pass my thought to friends, and thinking of letting more people could own Byron camera, I would held an experimental workshop, to help participant build one.

But the procedure could be very difficult if all by instructions only, there are some steps which needs special tooling, and some steps need CNC lathe machine, not everyone could find a helping hand around.

So I will ask participants follow my instruction, in some steps, to send their parts to me, I will help them to finish those steps, and then let them go on to next step.

I envision there will be about two steps for sending back parts, by sending back their parts, I will enclose all the parts needed for building Byron, including those tailored parts that I designed, exclusive for Byron.

The most complicated parts now I think most people will encounter, will be at the step building bellows, not yet decide whether I will make one for each other, or let them try, so there will be sort of experiments in it, participant not only need to be skillful on DIY, prepare all kinds of hand tools, and need a lot of patience, willing to help me to perfect the instruction, so there will be one complete instruction left when the camera is build, workshop at the end.

Workshop will take about 3 months for the course. It should start at the end of this month. Instruction will be released one by one, as a step for every two weeks,

Cost will be US$900, including all parts and two shipping postage during the course, but I am asking if anyone is interested in this way of DIY, let me know, mail me, all I need is about 4 participants, besides hand tools, you have to prepare your own Polaroid 110B plus lenses you choose, (or 110A + 900) and the conversion type (limited in Type A or B), drop me a mail, we could communicate privately.

If you are interested in this way, please let me know before 10/16. You are not really in the workshop by sending mail, just let me know if there are people who are interested.

thank you very much.

Daniel

salihonba@gmail.com

ps. DIY instructions will not be published in public, only participants are allowed to login and read it.

You can choose one Prime lens for matching cam curve, that is, your range-coupled lens. I will grind the cam curve for you, but I need you send the lens to me. other lenses you choose for Byron will be un-coupled range finding.

Thursday, September 29, 2011

Best dress for Byron camera

Bob made wonderful type 55 instant film, named New55, and he made some gorgeous test shots.

http://black-gallery.blogspot.com/

http://black-gallery.blogspot.com/

Saturday, September 24, 2011

Three types of Byron conversion

Byron has been developed for about 6 years, during the period, concluding clients' feedback and some more request, the conversion service now had been categorized into three types, according to client's lens selected.

Lenses' focal range are limited in 75~150mm, any lens with focal length lesser or greater are not feasible for Byron. 75mm lens is the widest lens Byron can bear, and even in this lens, there is some 4~5mm on side will be blocked by rail, please read the related post. But the situation has been improved, I managed to move the lens a bit higher, to bypass the barrier, so 75mm lens is the set.

Type A, Byron as snap shooter

Snap shoots on streets with a 4x5 format rangefolder is what the original idea when I developed Byron system, and the purpose needs a camera with speed on operation and as lightweight as possible.

Lens board for type A is in circular shape, about 60mm in diameter, when lens board threaded with #0 shutter, it is so tiny that you bare notice there exist a board with the lens, it takes no space, has advantages when traveling light, and stored in bag, that is important for street snaps.

Lenses selected based on the criteria mentioned above, we need lens could be stayed in camera when folded, so it could be ready to shoot whenever fold out, so lens should be tiny, shutter limited in #0 or even smaller, and the rear element should be no bigger than 44.8mm in diameter.

What the lenses I recommend for this type of conversion are:

Schneider Angulon 6.8/90mm

*Schneider Symmar-S 5.6/100mm

Carl Zeiss Tessar 4.5/105mm

Carl Zeiss Tessar 4.5/120mm

Rodenstock Ysarex 4.7/127mm (original lens on 110B camera)

*Fujinon W 5.6/135mm

**Rodenstock Geronar 6.3/150mm (or Caltar II-E 6.3/150mm)

They are all small enough to stay in camera when fold, and the image coverage is just enough for 4x5 format.

(*Lens must be taken off before camera folded.)

(**In type A conversion, 150mm lenses are limited in Geronar or Caltar II-E only, for they have shorter flange to focal image distance, which just great for type A conversion, other 150mm lenses such as Apo-Symmar 5.6/150, Apo-Ronar 9/150mm or Nikkor/Fuji lenses, their flange-focal image distance just exceed rail end, so they all fall into type B conversion, which has different front standard, can solve the longer f-f distance problem.)

Type B, Byron for those big rear lenses

Many modern design and better optical performance lenses have big front or rear elements, or with bigger aperture, bigger shutter.

Clients want to use them, and don't really care of the carrying issue or lens exchanging on field problem, they own these lenses already, and hope to migrant them onto Byron.

In this type, a new front standard and lens board system were developed to fulfill the purpose, any lens in #0 or #1 shutter is acceptable, and if the rear element is within 60mm in diameter, the lens could be mounted directly, no need to screw off the rear first. Due to the size, lens must be taken off before camera is folded.

What the lenses most situation I encounter, and they are able to be mounted directly without problems,

Rodenstock Grandagon-n 4.5/75mm (rear dia. 59.8mm)

Sinaron W 4.5/75mm (rear dia. 59.8mm)

Schneider Super Angulon 8/90mm (rear dia. 56.8mm)

Schneider symmar 5.6/100mm

Carl Zeiss Planar 2.8/100mm (in #1 shutter)

Schneider Angulon 6.8/120mm (in #1 shutter)

Schneider Xenotar 3.5/135mm (in #1 shutter, rear dia. 47.7mm)

Voigtlander Apo-Lanthar 4.5/150mm (in #1 shutter)

Voigtlander Heliar 4.5/150mm (in #1 shutter)

Schneider Apo Symmar 5.6/150mm

Rodenstock Apo Ronar 9/150mm

Nikkor/ Fuji 150mm lens

Type X, only for Xenotar 2.8/150mm

This is a big, heavy lens that many photographers want to use it on portrait for its bokeh, for this special lens, I have developed a variety from type B, exclusive for this lens.

Xenotar 2.8/150mm lens must be mounted on a #2 shutter, I know it is hard to find for such a shutter, but Byron just can not take normal #3 shutter anymore, too big in size.

The rear element is 62.85mm in diameter, Xenotar must first screw off the rear element, mount onto the standard, then screw back the rear.

Not only front standard needs to be enforced, rail and many other parts need to be re-adjust to allocate this big boy, the cam curve needs greater precision for its super shallow DOF too.

Oh, recently I saw other conversion service on ebay, also for Xenotar 2.8/150, although I did not see any image about the converted camera for Xenotar 2.8/150 yet, but the service charge do really THUNDERSTRUCK me a bit!

Lenses' focal range are limited in 75~150mm, any lens with focal length lesser or greater are not feasible for Byron. 75mm lens is the widest lens Byron can bear, and even in this lens, there is some 4~5mm on side will be blocked by rail, please read the related post. But the situation has been improved, I managed to move the lens a bit higher, to bypass the barrier, so 75mm lens is the set.

Type A, Byron as snap shooter

Snap shoots on streets with a 4x5 format rangefolder is what the original idea when I developed Byron system, and the purpose needs a camera with speed on operation and as lightweight as possible.

Lens board for type A is in circular shape, about 60mm in diameter, when lens board threaded with #0 shutter, it is so tiny that you bare notice there exist a board with the lens, it takes no space, has advantages when traveling light, and stored in bag, that is important for street snaps.

Lenses selected based on the criteria mentioned above, we need lens could be stayed in camera when folded, so it could be ready to shoot whenever fold out, so lens should be tiny, shutter limited in #0 or even smaller, and the rear element should be no bigger than 44.8mm in diameter.

What the lenses I recommend for this type of conversion are:

Schneider Angulon 6.8/90mm

*Schneider Symmar-S 5.6/100mm

Carl Zeiss Tessar 4.5/105mm

Carl Zeiss Tessar 4.5/120mm

Rodenstock Ysarex 4.7/127mm (original lens on 110B camera)

*Fujinon W 5.6/135mm

**Rodenstock Geronar 6.3/150mm (or Caltar II-E 6.3/150mm)

They are all small enough to stay in camera when fold, and the image coverage is just enough for 4x5 format.

(*Lens must be taken off before camera folded.)

(**In type A conversion, 150mm lenses are limited in Geronar or Caltar II-E only, for they have shorter flange to focal image distance, which just great for type A conversion, other 150mm lenses such as Apo-Symmar 5.6/150, Apo-Ronar 9/150mm or Nikkor/Fuji lenses, their flange-focal image distance just exceed rail end, so they all fall into type B conversion, which has different front standard, can solve the longer f-f distance problem.)

Type B, Byron for those big rear lenses

Many modern design and better optical performance lenses have big front or rear elements, or with bigger aperture, bigger shutter.

Clients want to use them, and don't really care of the carrying issue or lens exchanging on field problem, they own these lenses already, and hope to migrant them onto Byron.

In this type, a new front standard and lens board system were developed to fulfill the purpose, any lens in #0 or #1 shutter is acceptable, and if the rear element is within 60mm in diameter, the lens could be mounted directly, no need to screw off the rear first. Due to the size, lens must be taken off before camera is folded.

What the lenses most situation I encounter, and they are able to be mounted directly without problems,

Rodenstock Grandagon-n 4.5/75mm (rear dia. 59.8mm)

Sinaron W 4.5/75mm (rear dia. 59.8mm)

Schneider Super Angulon 8/90mm (rear dia. 56.8mm)

Schneider symmar 5.6/100mm

Carl Zeiss Planar 2.8/100mm (in #1 shutter)

Schneider Angulon 6.8/120mm (in #1 shutter)

Schneider Xenotar 3.5/135mm (in #1 shutter, rear dia. 47.7mm)

Voigtlander Apo-Lanthar 4.5/150mm (in #1 shutter)

Voigtlander Heliar 4.5/150mm (in #1 shutter)

Schneider Apo Symmar 5.6/150mm

Rodenstock Apo Ronar 9/150mm

Nikkor/ Fuji 150mm lens

Type X, only for Xenotar 2.8/150mm

This is a big, heavy lens that many photographers want to use it on portrait for its bokeh, for this special lens, I have developed a variety from type B, exclusive for this lens.

Xenotar 2.8/150mm lens must be mounted on a #2 shutter, I know it is hard to find for such a shutter, but Byron just can not take normal #3 shutter anymore, too big in size.

The rear element is 62.85mm in diameter, Xenotar must first screw off the rear element, mount onto the standard, then screw back the rear.

Not only front standard needs to be enforced, rail and many other parts need to be re-adjust to allocate this big boy, the cam curve needs greater precision for its super shallow DOF too.

Oh, recently I saw other conversion service on ebay, also for Xenotar 2.8/150, although I did not see any image about the converted camera for Xenotar 2.8/150 yet, but the service charge do really THUNDERSTRUCK me a bit!

Wednesday, September 14, 2011

Xenotar 135/3.5 on SL66

I dug my dehumidifier yesterday for my spared #2 shutter, and I found one long forgot Xenotar 135/3.5 sat there stared at me, I bought it last years, and then quickly shift my interest into big brother 150/2.8, this one left in the box till now.

It came as a barrel lens, with iris only, but I managed to fit it with a proper #1 shutter, and so there it can be mounted on Byron, or on my SL66.

This lens did not need extension tube, you can see bellows extends just about 1.5inch and you got infinity already, if you extend bellows to the end, focus can be as near as 1.5 feet.

Next time I will try to mount this beauty onto Byron, 135mm is quite wide for 4x5 snaps.

It came as a barrel lens, with iris only, but I managed to fit it with a proper #1 shutter, and so there it can be mounted on Byron, or on my SL66.

This lens did not need extension tube, you can see bellows extends just about 1.5inch and you got infinity already, if you extend bellows to the end, focus can be as near as 1.5 feet.

Next time I will try to mount this beauty onto Byron, 135mm is quite wide for 4x5 snaps.

Tuesday, September 13, 2011

How to read Kindle in bed with one hand

I love to read, especially while laying in bed, I can read all day in winter days, just head and hand outside of the blanket.

But with e-book like Kindle, it is nearly impossible to hold the device one hand only, it forces you to hold the device with two hands, or you will drop the book, or your hand feel awkward sour.

I searched the web, to see other people how they solve the problem, there are so many ppl love to read on bed, they must have good ideas to make the reading comfortable and cozy, but I hardly found one satisfy my need.

So I thought of many ways to "stick" Kindle in my palm, rubber band, silicon ring with wire, glove that with many small suckers...... and then this one is the most easy and comfort one.

All you need is a kitchen cleaning sponge, with a big silicon sucker in middle, to hold the sponge on wall tile. The cost is about US$1.5 here in Taiwan. we need the sucker only, let sponge stay in kitchen.

But with e-book like Kindle, it is nearly impossible to hold the device one hand only, it forces you to hold the device with two hands, or you will drop the book, or your hand feel awkward sour.

I searched the web, to see other people how they solve the problem, there are so many ppl love to read on bed, they must have good ideas to make the reading comfortable and cozy, but I hardly found one satisfy my need.

So I thought of many ways to "stick" Kindle in my palm, rubber band, silicon ring with wire, glove that with many small suckers...... and then this one is the most easy and comfort one.

All you need is a kitchen cleaning sponge, with a big silicon sucker in middle, to hold the sponge on wall tile. The cost is about US$1.5 here in Taiwan. we need the sucker only, let sponge stay in kitchen.

Make it suck at the back of the device, there you go, you can place it anywhere on the back, sometimes I read when at breakfast, I place the sucker at the middle top of the back, thus make it a good reading angle when placed on the table.

For improving the strength of sucker to hold, I use a piece of cutting sheet on back, make the sucker to hold the device, unless you pull it really hard, the sucker won't let go, no risk falling the device.

When laying in bed, I place it at lower corner, to fit my hand, so I can hold my Kindle one hand, and my thumb could help press the page down button.

Tuesday, September 6, 2011

cam curve for Geronar 6.3/150

The red curve is for 6.3/150mm Geronar lens.

Compare this lens with Xenotar, Heliar, apo-symmar 150 lenses, the curve is interesting different with them, Geronar has its own character, no wonder it has shortest rail movement for infinity stop.

Saturday, August 27, 2011

Consistency of RF mechanism

Had been measured and plotted 6 RF mechanisms last week, to verify their consistent performance, thus if they are, we can refer it as a constant, so the only variation of the cam curve is from lens focal performance.

To measure each one, mount the RF part, zeroing it by focus to infinity and make overlay images in window match well, then use this as zero point, focus at other distance, here I choose 8m, 7m, 6, 5, 4m, 3m, 2.4, 2.1m, 1.8m, 1.5, 1.2, 1.0m as target, and record the moving distance of the mirror arm, then plotting the curve representing the records.

To measure each one, mount the RF part, zeroing it by focus to infinity and make overlay images in window match well, then use this as zero point, focus at other distance, here I choose 8m, 7m, 6, 5, 4m, 3m, 2.4, 2.1m, 1.8m, 1.5, 1.2, 1.0m as target, and record the moving distance of the mirror arm, then plotting the curve representing the records.

Except curve No.4, all six curves has very similar character, indicates the RF mechanism is fairly consistent at their performance on focusing, but there DOES has mechanism like curve No.4, whose character is different, I would call it a "mine", for it is impossible to find out before you bought such a vintage camera produced sixty years ago, actually you could not expect too much. Luckily most people didn't convert 110B as an lens interchanging camera, so they never know.

Nevertheless, most of the RFs are good, but I prefer inspect one by one, before I made the dedicated cam grinding.

Thursday, August 11, 2011

Grinding Ground Glass

Never expect it so hard to buy grinding grit in Taiwan.

My previous version of gg panel was made of bakelite, and the ground glass is a piece of transparent acrylic sheet in 3mm thickness, frosted surface is from a thin layer of laminator sheet sandwiched between Fresnel lens and acrylic sheet.

Laminate sheet sleeve is for laminator to hot press the sandwiched photos or id card, to form a protect cover, very thin, fine evenly distributed frosted surface, but after hot press and rolled out from laminator, it becomes transparent. It is easy to get in any stationary store, and in 100sheet pack, you can choose any size you want, in my case, 4x6 inch sleeve is enough, I had to cut some edges.

I tried Scotch Magic tape before, but in my own opinion, laminator sheet is better.

Last week I received new version aluminum gg panel, some minor modifications from previous version. Panel surface was sand blasted and dyed in matte black, looked much better quality than bakelite one. I put in Fresnel lens, laminator sheet, and then finally acrylic sheet on top, fixed with folding hood and six screws with washers. Left one is the new version, six big washer help fix the hood also the ground glass, and screw holes on hood edges are far more robust than old version, not easy to crack anymore, and looks more flat at side.

But then I compared my gg panel with the one on my Linhof Tech IV, first focus with Linhof gg panel, then replace it with my panel, my frosted surface obviously coarser, thought the focal point is dead on.

I thought that Byron is dedicated for snaps, and gg panel is for occasionally used as view camera, so the gg panel is not so critical. But as some requests from clients asking for better quality ground glass, and since the panel is upgraded from bakelite to aluminum, maybe I should consider a finer frosted surface.

I ordered some 3mm thick glass panels, and acrylic panels too.

There are articles about "how to make your own ground glass", easy to find them on web, but the grinding grit, aluminum oxide in 15 micron is not a common product to find in Taiwan's auction market, I made some calls, and most of store sells them in bulk package, 20 or 25kg, that is too much to me, I can use it for the rest of my life and to my son, and to my grandson!

Finally a shop is willing selling me in 2kg package, but in higher price, what can I say? I almost kneel down and kiss his feet.

Took a glass sheet in about A2 size as plate, I sprayed a tea spoonful of grit on it, with some drips of water, then acrylic panel face down, I began to made rotate grinding on it.

That's about another 5minutes, then a panel with evenly frosted surface is done! With same way I make glass panel too, comparing two panels as ground glass, I can not tell the difference.

But since I made frosted glass myself, I should compare new panel (Fresnel lens+ frosted acrylic sheet) with older panel (Fresnel lens+ laminate sheet+ transparent acrylic sheet), to see if there any improvement.

I focused the same object, with two versions of gg panel.

This is from old version (Fresnel lens+ laminate sheet+ transparent acrylic sheet), there is some circular pattern on frosted surface, that is from Fresnel lens.

And this is from new version, Fresnel lens+ frosted acrylic sheet. Fresnel lens pattern is also distinguishable, but less than old one.

It's not so obviously to tell in taken images, but it's easy to tell by naked eyes that frosted acrylic is finer than laminate sheet with transparent acrylic.

But there will be two options for clients to choose, acrylic sheet is lighter and not so easy to crack if falling; while glass sheet is heavier and prone to crack if falling on floor, but better scratch resistance.

Which one will you choose? Acrylic? Glass?

My previous version of gg panel was made of bakelite, and the ground glass is a piece of transparent acrylic sheet in 3mm thickness, frosted surface is from a thin layer of laminator sheet sandwiched between Fresnel lens and acrylic sheet.

Laminate sheet sleeve is for laminator to hot press the sandwiched photos or id card, to form a protect cover, very thin, fine evenly distributed frosted surface, but after hot press and rolled out from laminator, it becomes transparent. It is easy to get in any stationary store, and in 100sheet pack, you can choose any size you want, in my case, 4x6 inch sleeve is enough, I had to cut some edges.

I tried Scotch Magic tape before, but in my own opinion, laminator sheet is better.

I thought that Byron is dedicated for snaps, and gg panel is for occasionally used as view camera, so the gg panel is not so critical. But as some requests from clients asking for better quality ground glass, and since the panel is upgraded from bakelite to aluminum, maybe I should consider a finer frosted surface.

I ordered some 3mm thick glass panels, and acrylic panels too.

There are articles about "how to make your own ground glass", easy to find them on web, but the grinding grit, aluminum oxide in 15 micron is not a common product to find in Taiwan's auction market, I made some calls, and most of store sells them in bulk package, 20 or 25kg, that is too much to me, I can use it for the rest of my life and to my son, and to my grandson!

Finally a shop is willing selling me in 2kg package, but in higher price, what can I say? I almost kneel down and kiss his feet.

Took a glass sheet in about A2 size as plate, I sprayed a tea spoonful of grit on it, with some drips of water, then acrylic panel face down, I began to made rotate grinding on it.

To made it easier to hold the panel while in grinding, I used a silicon sucker which has a big handle on it, so rotate the panel on glass is smooth and easy, no fingers directly touch the panel, avoiding any chance that wrong side of sheet got ground.

About 5 min for a panel, then I immersed the panel into water, wiped it with a towel, to check if there is any hot spot, there is, especially at the center, means that sucker makes center get less pressure, so I had to leave the panel away, with fingers evenly pressed on panel, make second rotation grinding.

But since I made frosted glass myself, I should compare new panel (Fresnel lens+ frosted acrylic sheet) with older panel (Fresnel lens+ laminate sheet+ transparent acrylic sheet), to see if there any improvement.

I focused the same object, with two versions of gg panel.

This is from old version (Fresnel lens+ laminate sheet+ transparent acrylic sheet), there is some circular pattern on frosted surface, that is from Fresnel lens.

It's not so obviously to tell in taken images, but it's easy to tell by naked eyes that frosted acrylic is finer than laminate sheet with transparent acrylic.

But there will be two options for clients to choose, acrylic sheet is lighter and not so easy to crack if falling; while glass sheet is heavier and prone to crack if falling on floor, but better scratch resistance.

Which one will you choose? Acrylic? Glass?

Friday, July 29, 2011

OMG!

Too hot these days, one of my assistant crafts master got stroke when he practiced kendo, and in Persistent vegetative state now, what a pity!

He is only 54 now.

He is only 54 now.

Saturday, July 23, 2011

busy week

This week I'm gonna finish this conversion batch, forgive me for no further information on RF.

Wednesday, July 13, 2011

Some Ideas on Range-Coupled mechanism

Thinking of range-coupled mechanism these days, just came out of some ideas. No matter Linhof or Graphic, Horseman or other brands 4x5 cameras, if installed with rangefinders, all need a match cam for specific lens, otherwise no range-coupled functions available.

People are troubled when they tried to find lens and matched lens cam, the pair are rare to find these days, and the price always sky high, handheld 4x5 photography restricted by this, so called range coupled 4x5 almost vanished.

What if

Too excited! can not sleep at night.

an interesting discussion here:

http://www.largeformatphotography.info/forum/showthread.php?t=79196

People are troubled when they tried to find lens and matched lens cam, the pair are rare to find these days, and the price always sky high, handheld 4x5 photography restricted by this, so called range coupled 4x5 almost vanished.

What if

- Range coupled function needs no match lens cam.

- Any lens can be range coupled, no matter what camera used.

- Lens calibration needs no professional expert. one lens can be calibrated in 10 minutes.

Too excited! can not sleep at night.

an interesting discussion here:

http://www.largeformatphotography.info/forum/showthread.php?t=79196

Friday, July 8, 2011

Rangefinder calibrations on 110B- part6

Now there goes to final part of RF calibration.

We match the lens with rangefinder with a tailored cam, so camera can be range coupled with ONE specific lens, but that is all it can do, if you want to use other lenses, these lenses are range UN-coupled, that is, rangefinder as a pure rangefinder only, reading out the rangefinder indicates, then we adjust the lens position to match the focus.

What if we could change this ONE-LENS-ONLY range coupled camera into a multi-lenses RF camera? I thought about this for years, and many clients asked the same question also, everyone wants multi range coupled function.

Here I list some issues on this conversion as follow:

Multi cam

More than one lens range coupled needs more than one more cam, how many cam possibly be installed on a camera?

As we measured, each cam needs at least 40° of rotation, so as 360° divided by 40°, maximum we can make 8 cams simultaneously be installed on one camera, but that is too much and too complicated, I would say 3 cams is enough.

Each cam separated and distributed at every 120°, that leaves enough space and tolerance to mechanism.

Field operations

If we solve all the problem mentioned above, the final problem arise as how to operate this mechanism in field. We need a knob to rotate the cam pole, to match the lens we change, that involves changing the outlook of the RF housing, but pity there is no space for it in my opinion, best way is to re-design and re-mold the RF housing, but consider the quantity and mold making cost, I stop at this place and never go any further.

We match the lens with rangefinder with a tailored cam, so camera can be range coupled with ONE specific lens, but that is all it can do, if you want to use other lenses, these lenses are range UN-coupled, that is, rangefinder as a pure rangefinder only, reading out the rangefinder indicates, then we adjust the lens position to match the focus.

What if we could change this ONE-LENS-ONLY range coupled camera into a multi-lenses RF camera? I thought about this for years, and many clients asked the same question also, everyone wants multi range coupled function.

Here I list some issues on this conversion as follow:

Multi cam

More than one lens range coupled needs more than one more cam, how many cam possibly be installed on a camera?

As we measured, each cam needs at least 40° of rotation, so as 360° divided by 40°, maximum we can make 8 cams simultaneously be installed on one camera, but that is too much and too complicated, I would say 3 cams is enough.

Each cam separated and distributed at every 120°, that leaves enough space and tolerance to mechanism.

Stacked cam and rotating pole shape

Each cam curve is dedicated to match a specific lens, there may be differences between lenses, although they are in the same focal length, or even the same type. So it is impossible to order a batch of 3-in-1 cams that restrict clients to use only 3 pre-defined lenses, and since lens has its own character, to amend the outer curve in such a 3-in-1 is tiresome.

Best way is to separated each cam, stack 3 in a row according to each client's specific request.

But for keeping these cam staying at their rotating angle (120°), we should change the rotating pole from circular shape into a triangular shape.

Mirror arm and cams

As mentioned above, best way for multi-cam is to stack them to match the clients' request, but the original shape of the cam is un-stack-able, it is too thick.

You can see that original cam is thick to mirror arm, so this installation is unfeasible to 3-in-1 stack cam design, what we should do, is to reverse the mirror arm- cam relation, that is , to make mirror arm a thick arm, and make the cam a thin metal sheet. Such arrangement makes mirror arm easily be triggered by stacked cams, and metal sheet cam makes stacked thickness in bearable range. And the greatest advantage is to make cam much easier to file, to tailor its outer curve to match the lens character.

Field operations

If we solve all the problem mentioned above, the final problem arise as how to operate this mechanism in field. We need a knob to rotate the cam pole, to match the lens we change, that involves changing the outlook of the RF housing, but pity there is no space for it in my opinion, best way is to re-design and re-mold the RF housing, but consider the quantity and mold making cost, I stop at this place and never go any further.

Subscribe to:

Posts (Atom)